STEIN LD Floating Friction Device

STEIN LD Floating Friction Device

The all-new LD Invert-A-Wrap Range.

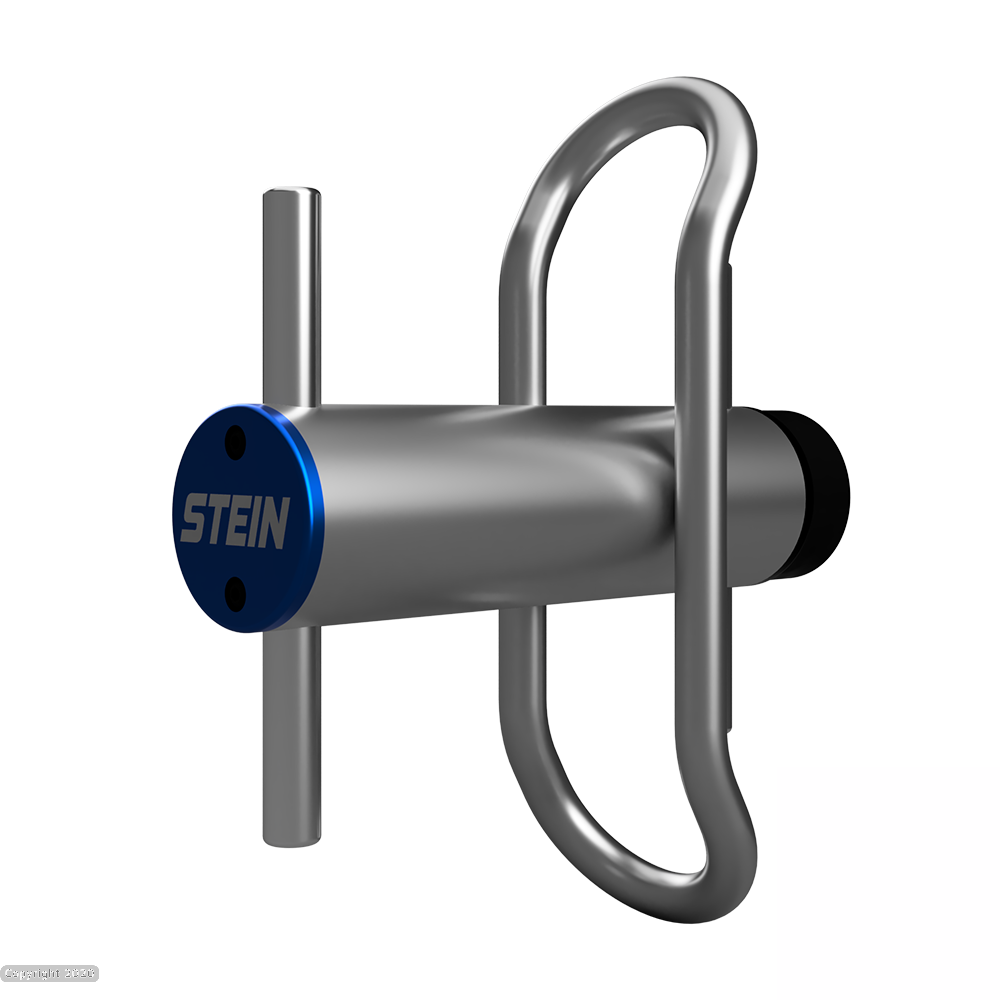

The Invert-A-Wrap is a cost-effective rope friction device designed for lowering timber / objects from an elevated position in a controlled manner.The user-friendly design can be mounted in either orientation and allows for a STEIN Hauler Kit to be attached so loads can either be raised prior to lowering or to assist in pre-tensioning the rigging line.

The Invert-A-Wrap is fitted with replaceable Fairleads allowing for the rigging line to be tied off if required and also act as redirects so the user can operate the Invert-A-Wrap from a safe distance.

For added protection the Invert-A-Wrap is fitted with a removable / replaceable protection rubber. This rubber helps protect

the structure the device is mounted to and also covers and protects the Product Information which includes a unique serial

number for traceability for inspections.

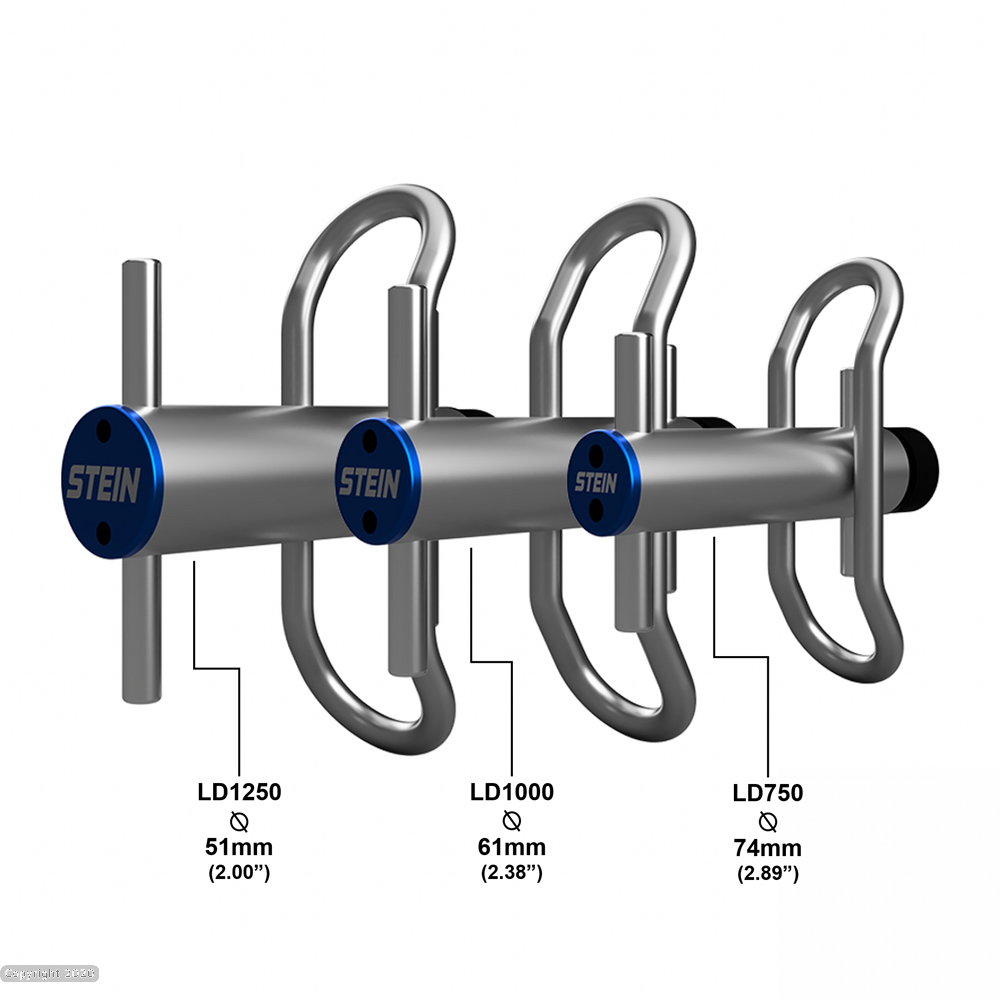

Available in 3 Sizes

| Model Number: | LD750 | LD1000 | LD1250 |

| Max Rope Diameter: | 13mm (1/2”) | 14mm (9/16”) | 16mm (5/8”) |

| Working Load Limit: | 750kg WLL (1650lbs) | 1000kg WLL (2200lbs) | 1250kg WLL (2755lbs) |

| Weight: | 1.925kg (4.25lbs) | 3.300kg (7.25lbs) | 4.430kg (9.75lbs) |

The STEIN Invert-A-Wrap is a Registered Design 4028823

Warning

Activities using this type of equipment are inherently dangerous. It is not possible to cover every eventuality relating to the

use of this equipment. Purchasers and users should seek professional training from a fully qualified and competent instructor prior to engaging in any activity. If you are not able, or not in a position to assume this responsibility, do not use this product. The manufacturer its distributors and retailers do not accept any liability if users do not follow the instructions correctly. Only the techniques shown in the diagrams are authorised. Any other use deviating from those shown may result in serious injury or death. Prior to each use a complete risk assessment must be carried out to ascertain that the device chosen configures with and is appropriate to the work being undertaken. As part of any method statement we recommend that all users of this equipment are given a copy of the instructions. They must read them, understand them and explicitly follow all instructions and cautions attached. Any person using this equipment should be fully trained and competent in its use

Share